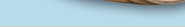

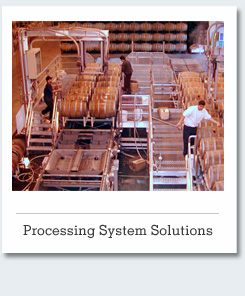

Models TBC2CL and TBC4CL are complete Barrel Processing Systems designed to handle barrels while they are still on the racks. TBC offers barrel processing systems that will accommodate both 2 & 4 barrel racks. The design of the system is modular and consists of conveyor sections that house washers, rollers, and lees recovery elements. Overhead structures carry emptying and filling arrays which automatically transfer wine to and from the barrels. These structures easily convert to mixing stations for stirring lees in fermenting barrels. The modular design allows the system to be tailored to the exact production requirements of each cellar. These systems can range from small and simple, to large and complex, depending on the functionality required, and the space available.

- TBC System Advantage

- Custom Design

|

TBC2CL & TBC4CL Advantage Proudly built in the U.S.A |

|

Tom Beard Company - Custom Design

The Design Team at Tom Beard Company has been setting the standard for barrel cleaning and sanitation for over 35 years. If you have a requirement that can not be met by our stock machines, we can probably design a solution that will work well for you. |